Length rewinder on PVC tube

Customer business sector :Fluid filtration, treatment and recycling

Length rewinder on PVC tube

Customer business sector :Fluid filtration, treatment and recycling

The customer requires a machine able to wind filter media onto a plastic mandrel to create a filter cartridge. Two key elements of the specification are essential to achieve this objective. Firstly, the machine must be able to maintain a constant tension when winding each turn of filter media. This ensures that the fluid is uniformly distributed over the entire surface of the filter cartridge as it passes through. Secondly, it’s important to have precise control over the outside diameter of the roll so that it fits perfectly, with millimeter precision, into the filter cartridge.

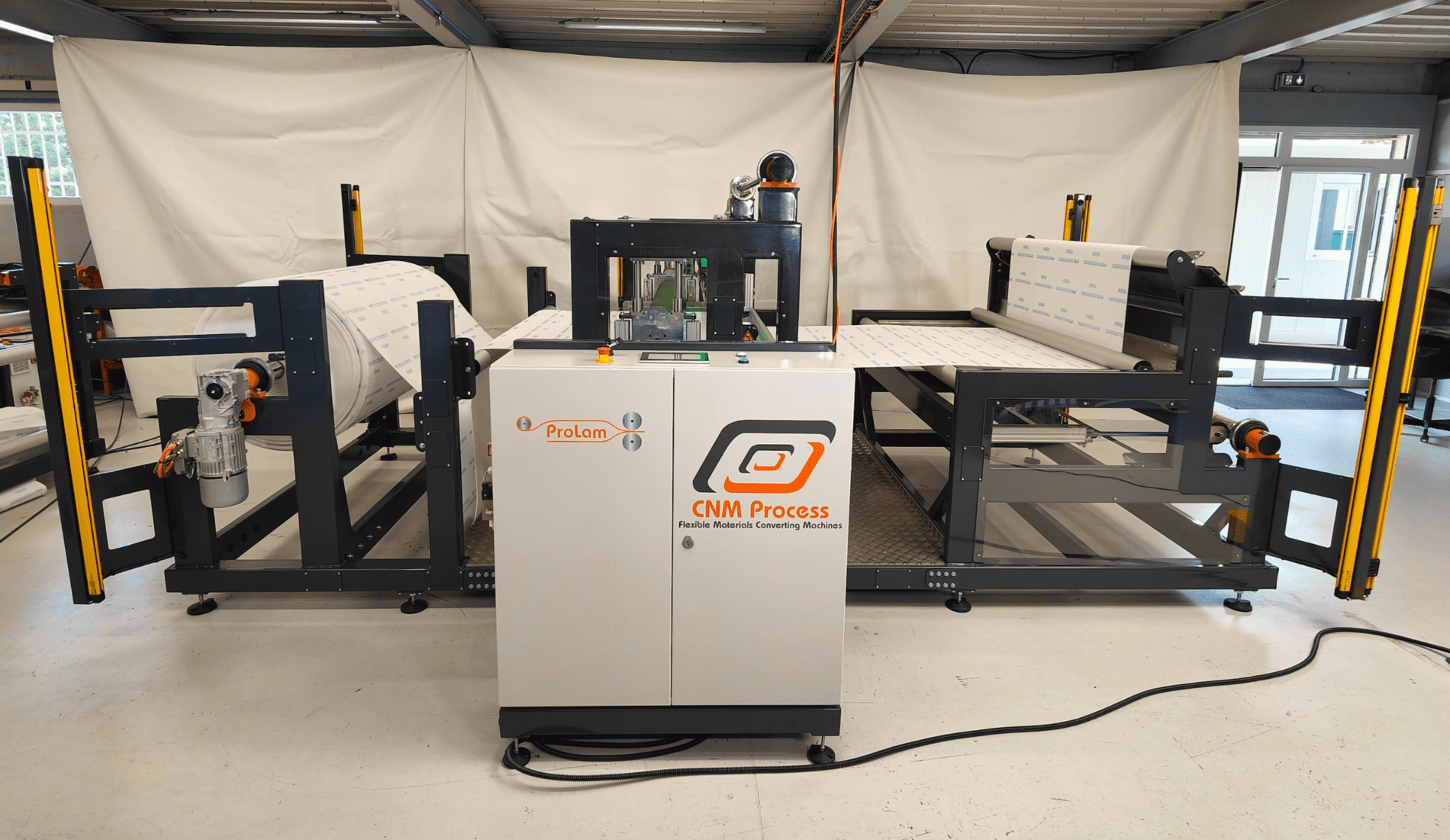

CNM has developed a complete solution based on the architecture of its Prolam range to meet the customer’s needs. The solution includes several key modules. At the machine input, a jumbo unwinder handles rolls of filter media with a diameter of less than 1200 mm. The calendering system, equipped with a dual motor drive, enables precise control of the material feed, guaranteeing even feed without crushing.

At the calender output, two cutting modules are used, equipped with motorized carbide-faceted blades, offering the possibility of delaizage or slitting in two to produce filter cartridges with specific widths as required.

The output splicing table is equipped with manually-operated electric scissors for precise, clean cutting. A winder with tension control based on diameter calculation is also integrated, guaranteeing constant tension and uniform winding of the filter media onto the plastic mandrel. In addition, a pressure roll with different operating modes is used to compact the windings, avoiding excessive tension on the material and ensuring high-quality winding.

The machine has a number of key strengths, especially its exceptional precision in controlling the winding process, and its great flexibility in managing parameters to achieve the desired result. These features were highly appreciated when we took delivery of the machine.