Machine

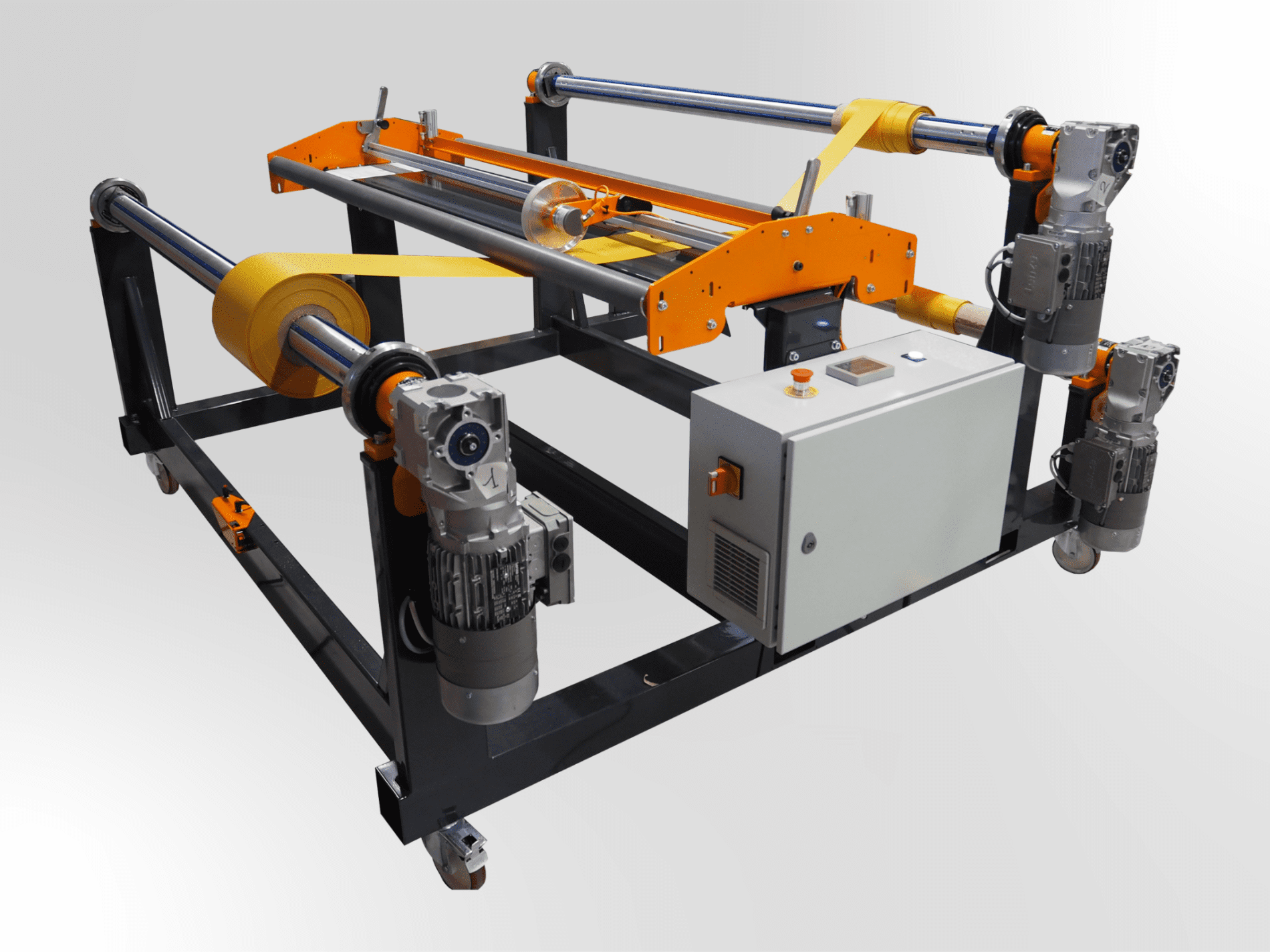

Slitter rewinder

Machine designed for winding to length and slitting/unwinding flexible materials.

Input: 3 feeder technologies depending on the material:

Unwinder

With mechanical brake

Motorized unwinder

with tension control

by material loop (0N)

Unwinder with dancer

at compensation

mechanic or pneumatic

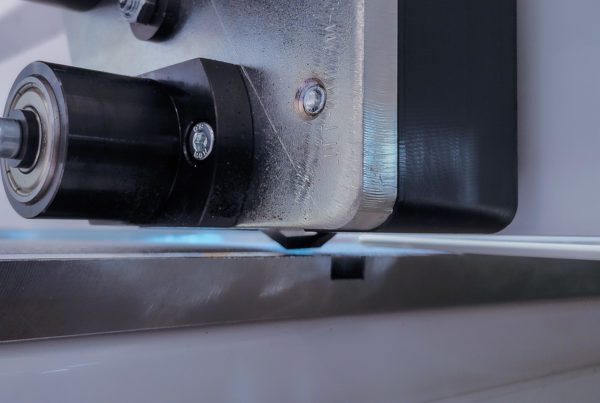

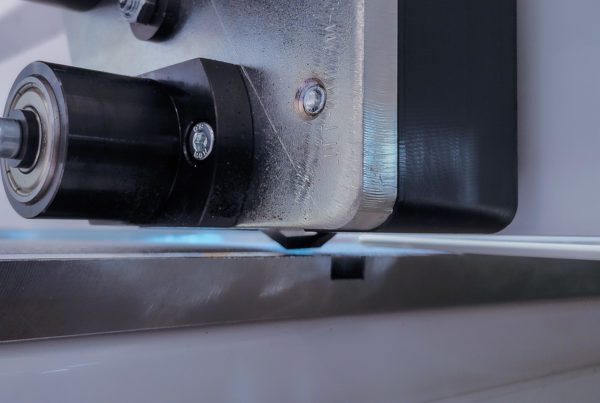

The cutting module consists of a call group and a cutting unit. Several cutting technologies are available for different materials.

At the output, the strips are rewind onto 2 expanding shafts, or alternately, for loading and unloading in masked time.

Safety is a key concern for us, and several solutions are available to meet your specific needs.

Various complementary modules can be integrated on request, such as a fitting table, vision system, etc.

The benefits

Efficient with all types of material: our winders work with all types of material, and thanks to our different unwinding and cutting systems, we can cover all types of flexible material, ensuring impeccable results.

Unprecedented versatility and ease of use: the machine’s digital control system ensures complete, automated management of the work cycle, with parameters recorded in production recipes.

Different degrees of automation depending on your needs: whether unwinding, slitting or rewinding, we have several systems available, each providing a specific solution. For example, in the case of frequent roll changes, the expanding shafts can be cantilevered or pivoted. For frequent changes in cutting width, a fully automatic solution is available…

Simplicity of loading and adjustment without compromising operator safety: the cutter bar lifts up to facilitate material positioning, the position being ensured by a mechanical indexing device. A laser line simplifies roll positioning.

In addition, the knives are usually mounted on blade holders for quick and easy adjustment of cutting widths. The design of the knife holders enables them to be changed without dismantling the blade holders, and each blade holder can be removed individually.

Two safety systems are available: a mechanical housing with an opening of less than 6 mm (economical solution), or a safety light curtains for easy maintenance access.

Caractéristiques techniques

Widths

Rolls Ø max.

Working speed

Max. roll weight

Max. cutting thickness

Minimum slitting width

Number of blades

Cutting systems

- Films / Adhésives

- Textiles

- Technical textiles / Thin foams

- Spunbond

- Thick foams / Felt / Rubber

- Papers

- Composites / All types of thin materials

- Others

Razor blades

Easy to set up

Economic system

Pressure knives on chrome-plated steel roller

Wide range of materials

Recommended for adhesives

Quick and easy adjustment

Train of motorized circular blades in pressure on steel counter-roller

High cutting accuracy

Cutting width defined by rectified spacers

Dimension change by replacement of the complete group

Motorized circular blades on cutting forks

Pollution-free cutting

Pressure knives on chrome-plated steel roller

Wide range of materials

Recommended for adhesives

Quick and easy adjustment

Train of motorized circular blades in pressure on steel counter-roller

High cutting accuracy

Cutting width defined by rectified spacers

Dimension change by replacement of the complete group

Pressure knives on chrome-plated steel roller

Wide range of materials

Recommended for adhesives

Quick and easy adjustment

Faceted carbide blade on felt-coated roller

Cut with scissor effect

No material constraints

Small and compact

Train of motorized circular blades in pressure on steel counter-roller

High cutting accuracy

Cutting width defined by rectified spacers

Dimension change by replacement of the complete group

Motorized circular blades on nylon logs

Cuts even the most difficult materials to the highest quality

Exceptional cutting quality in PE foam

Various blade diameters can be fitted to the blade holder

Perfect replacement for pressure knives when they are out of capacity

Blade counter-blade

Pollution-free cutting

Long knife life

Faceted carbide blade on felt-coated roller

Cut with scissor effect

No material constraints

Small and compact

Any special requests?

Contact us to discuss your needs.

Our aim is to offer our customers the most appropriate solution from a technological, strategic and economic point of view.