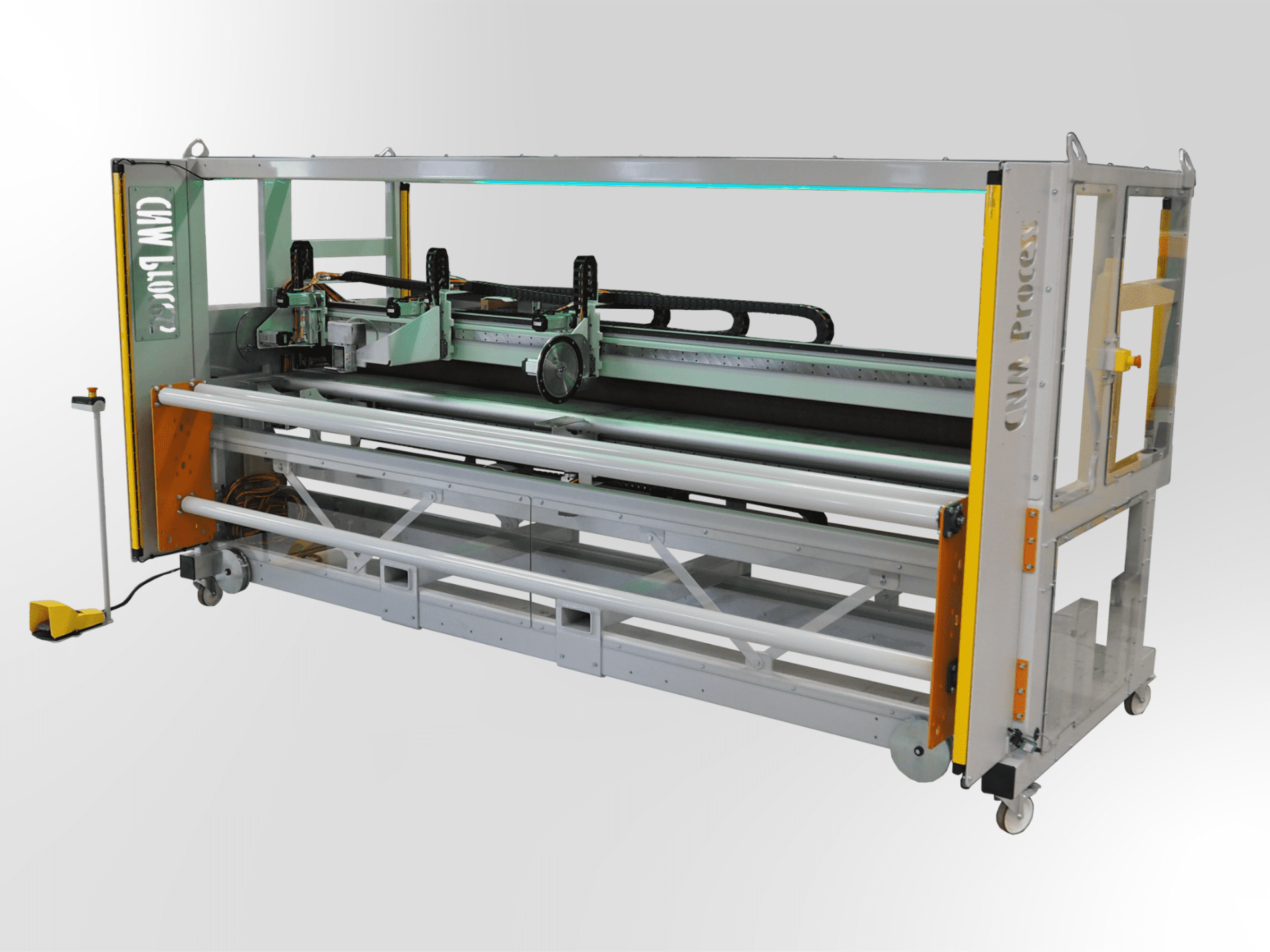

Machine

Format cutters

Machines designed for winding to length, slitting flexible materials, and cutting parts to size.

This machine stands out for its automatic management of cut size, and in particular the automatic adjustment of longitudinal cutting blades.

The machine is designed for high productivity, with ergonomic access to work areas without compromising operator safety. The touch screen display has been developed to support the operator at every stage of loading and adjustment.

The display’s articulated arm simplifies access to controls for all settings.

Customization and special versions on request

The benefits

This machine was originally designed for cutting textiles to size for the bedding industry. Other applications also exist, such as cutting tarpaulins for storage tents, or preparing materials for the automotive industry.

Thanks to an intuitive HMI, changing cutting widths has never been so quick and easy. We have successfully met the challenge of increasing productivity and cutting precision, while making the operator’s job safer. Automatic adjustment of cutting widths by servomotor, motorized blades and counter-blades. A specific cycle in the form of a tutorial has been designed to assist the operator when changing material or format.

Once the formats have been cut, different handling systems are available, depending on the customer’s requirements. Stacking of parts on oscillating bars is one possibility, as is stacking on pallets by conveyor belts…

Cutting systems

- Films / Adhesives

- Technical textiles / Thin foams

- Spunbond

- Thick foams / Felt / Rubber

- Papers

- Composites / All types of thin materials

- Textiles

- Others

Razor blades

Easy to install

Economic system

Pressure knives on chrome-plated steel roller

Wide range of materials

Recommended for adhesives

Quick and easy adjustment

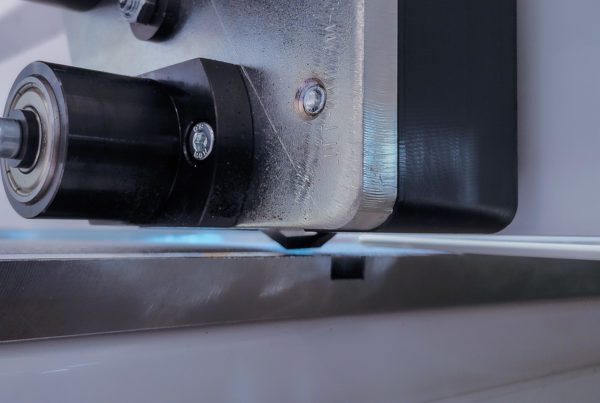

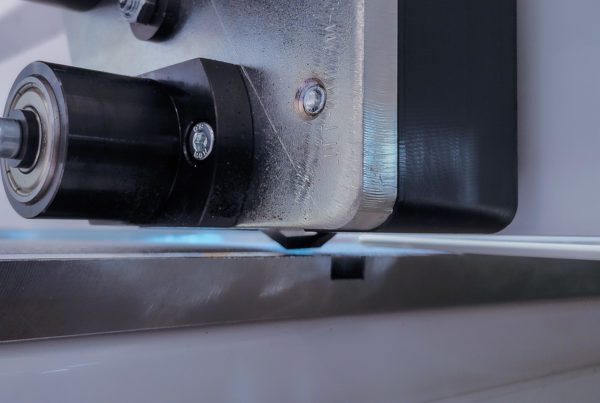

Train of motorized circular blades in pressure on steel counter-roller

High cutting accuracy

Cutting width defined by rectified spacers

Dimension change by replacement of the complete group

Pressure knives on chrome-plated steel roller

Wide range of materials

Recommended for adhesives

Quick and easy adjustment

Train of motorized circular blades in pressure on steel counter-roller

High cutting accuracy

Cutting width defined by rectified spacers

Dimension change by replacement of the complete group

Pressure knives on chrome-plated steel roller

Wide range of materials

Recommended for adhesives

Quick and easy adjustment

Faceted carbide blade on felt-coated roller

Cut with scissor effect

No material constraints

Small and compact

Train of motorized circular blades in pressure on steel counter-roller

High cutting accuracy

Cutting width defined by rectified spacers

Dimension change by replacement of the complete group

Motorized circular blades on nylon logs

Cuts even the most difficult materials to the highest quality

Exceptional cutting quality in PE foam

Various blade diameters can be fitted to the blade holder

Perfect replacement for pressure knives when they are out of capacity

Blade counter-blade

Pollution-free cutting

Long knife life

Faceted carbide blade on felt-coated roller

Cut with scissor effect

No material constraints

Small and compact

Motorized circular blades on cutting forks

Pollution-free cutting

Any special requests?

Contact us to discuss your needs.

Our aim is to offer our customers the most appropriate solution from a technological, strategic and economic point of view.