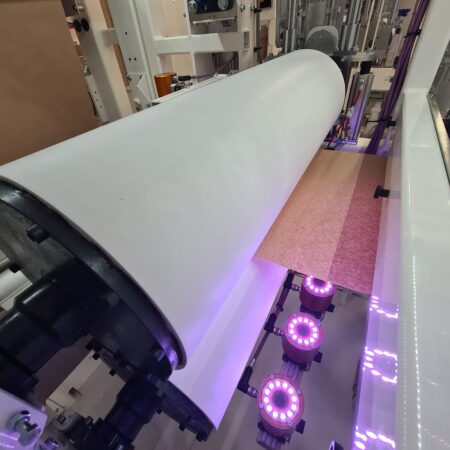

Machine

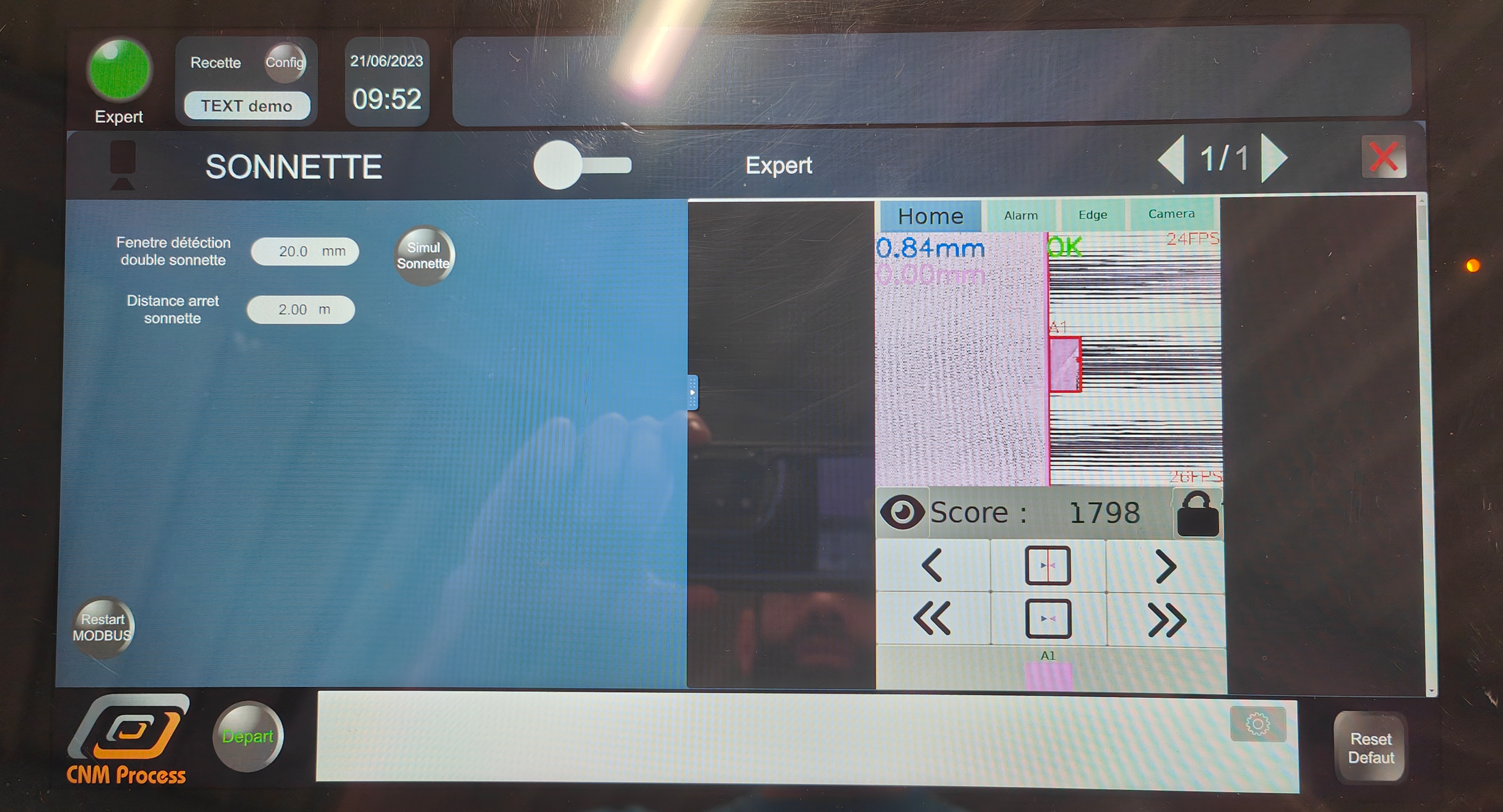

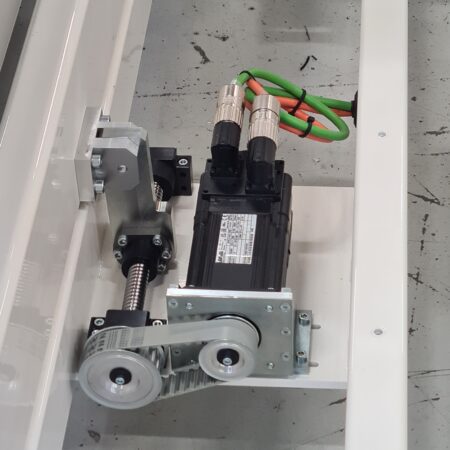

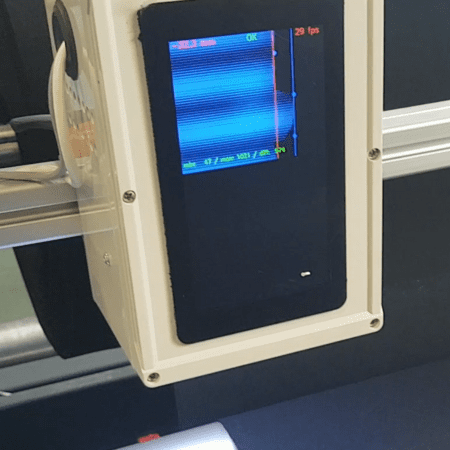

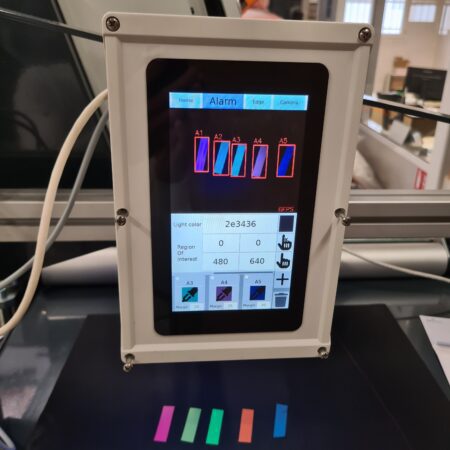

Vision system

Our vision system is developed in-house from start to finish. In fact, the camera and PLC have been programmed, enabling us, for example, to adapt different degrees of detection to different materials.

This system allows us to achieve unprecedented precision in process management and line automation.

Our camera enables border tracking, automatic realignment, defects detection and labels detection.

Several functions are available to suit your needs.

Available on all our machines!

Operating modes

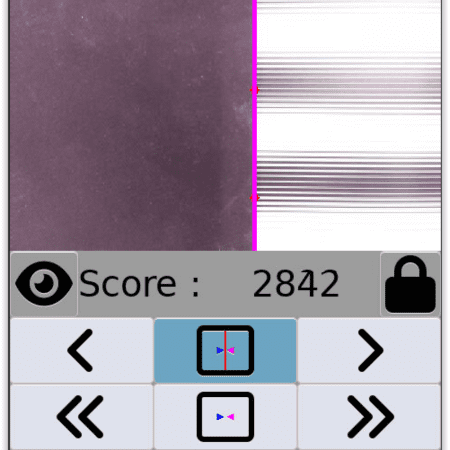

Edge tracking

Our camera is powerful enough to detect a border through a liner (composites)

Automatic realignment

Instant re-alignment by moving complete unwinding module

Irregular edges

Material edge detection is performed by point averaging, which is very effective on materials with irregular edges (textiles, composites, foams).

Change of references

Thanks to an intuitive system, the origin / reference can be easily modified during the process.

Defect detection

The fault zone is analyzed by the camera, and this information can be relayed to eliminate the fault zone. It is possible to integrate a stop at a precise length for faulty zones without interrupting the cycle.

Labels detection

The PLC designed by CNM Process is capable of detecting different colors and associating directives with each of them (stop, cut, feedback, etc.).