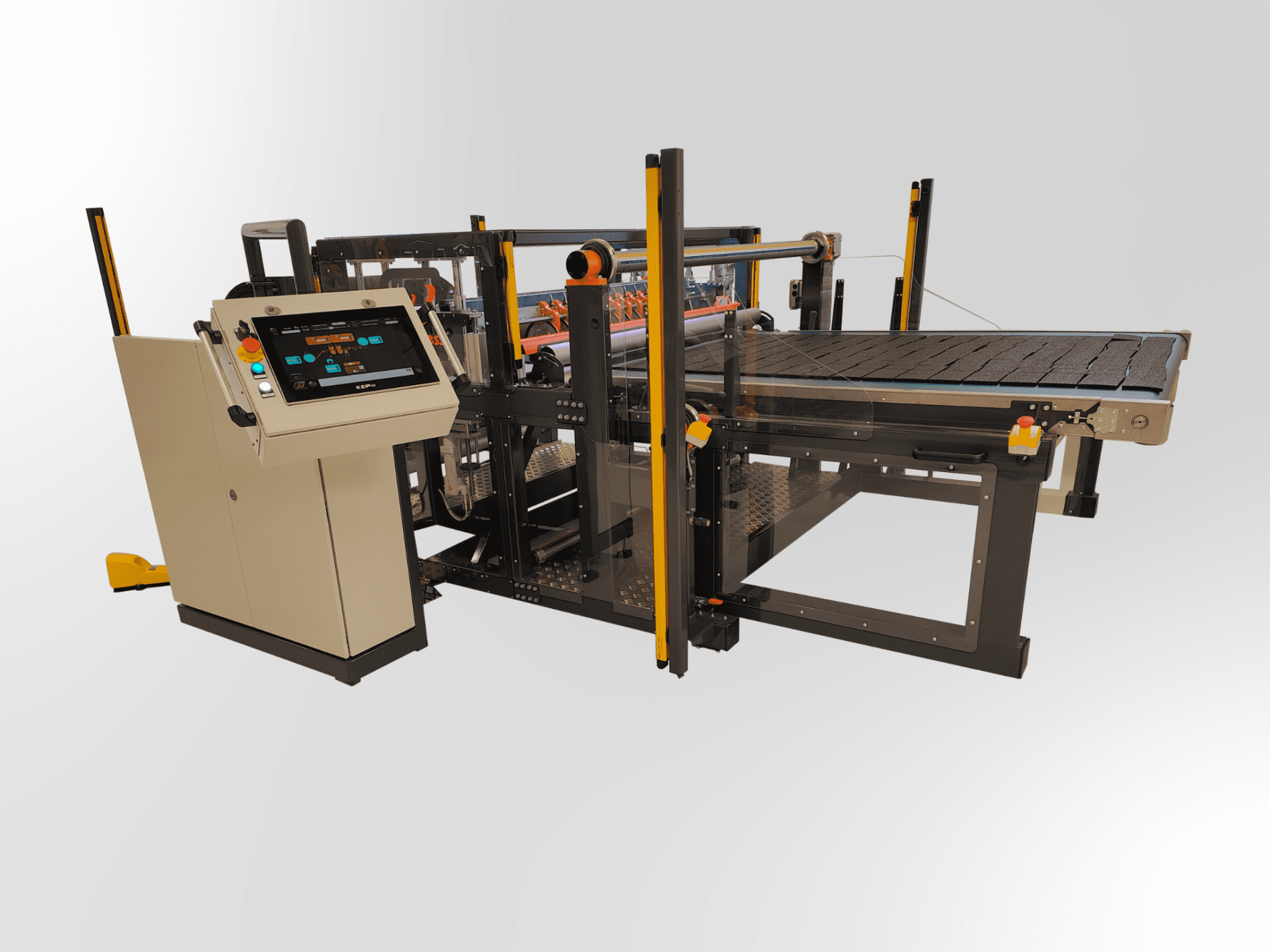

Machine PROLAM

Foams converters

Unwinding / Input conveyor – Lamibating – Slitting – Rewinding / Output tabele

Ideal for foams converters

Automatic pieces setting

The converting line for foam converters offers a complete range of equipment for the efficient processing and conversion of foam materials. The machine configuration includes various key stages, such as unwinding, input conveyor, laminating, slitting and rewinding with an output table.

The first stage of the converting line is unwinding, where foam rolls are unwind to feed the process. Thanks to a precise, controlled unwinding system, the foam sheets are conveyed smoothly and steadily to the next stages of the converting process.

Next, the input conveyor ensures smooth transfer of the foam sheets to the complexing stage. Complexing enables several layers of material to be superposed.

The CNM Process converting line ensures automatic stepping of the foam sheets, ensuring optimum precision and consistency in the complexing process.

After complexing, the slitting stage cuts the superposed foam sheets into strips or specific dimensions. This step is essential to obtain finished products with precise dimensions tailored to customer requirements. CNM Process offers a machine configuration that enables fast, accurate slitting, ensuring high productivity and consistent quality of finished products.

Finally, the finished product can be rewind at the exit. An exit table is also available to facilitate handling of the final products. This configuration guarantees smooth production, efficient automation and ease of use for foam converters.

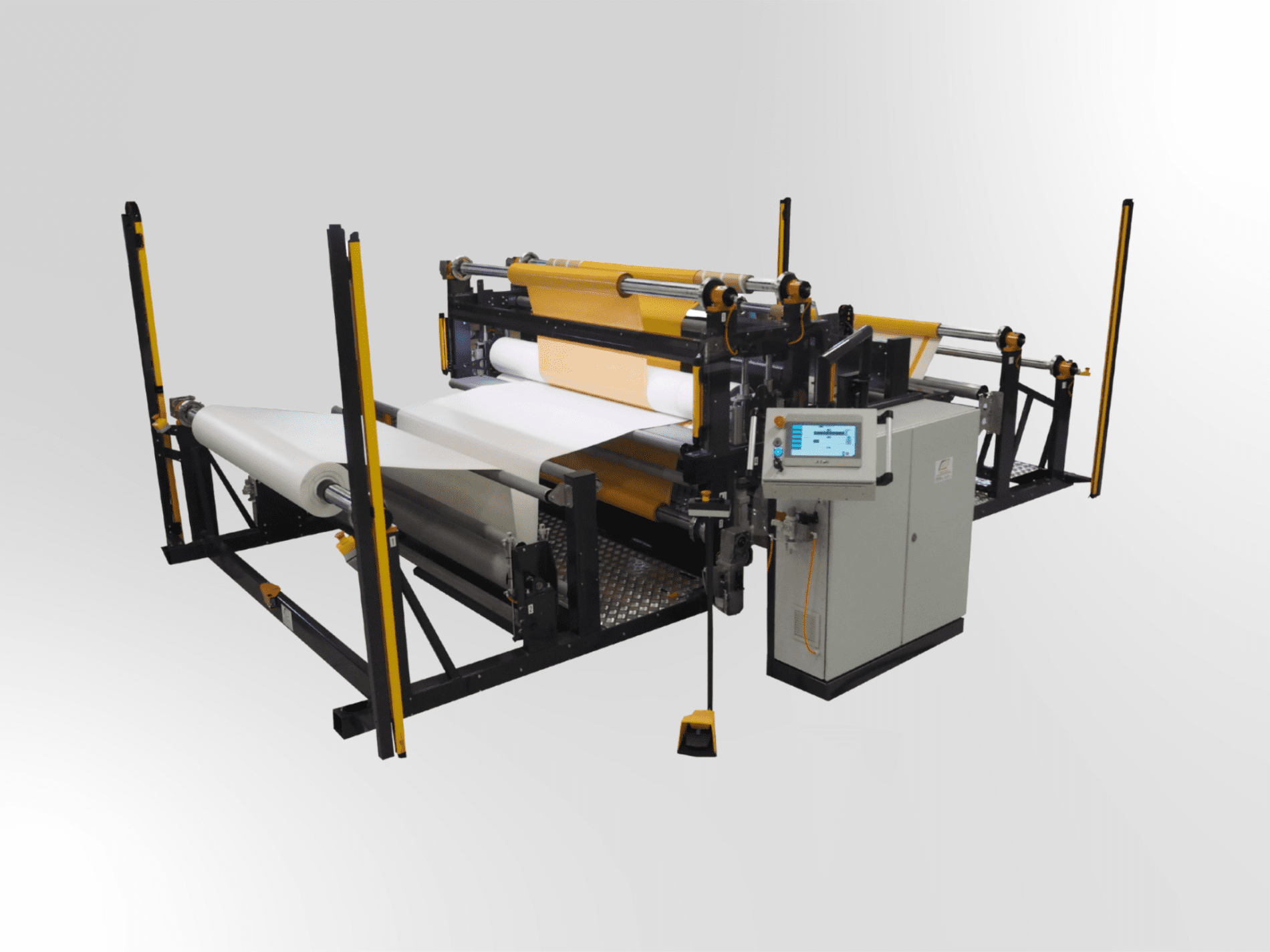

The others configurations

Rubbers converters

Unwinding – Laminating – Cross cutting – Output conveyor

Ideal for rubbers converters

No stress on pieces at the end of the line

Adhesives converters

Unwinding – Double sides laminating – Liner Removal – Slitting – Rewinding

Ideal for adhesives converters

Application of thin-width adhesives on borders