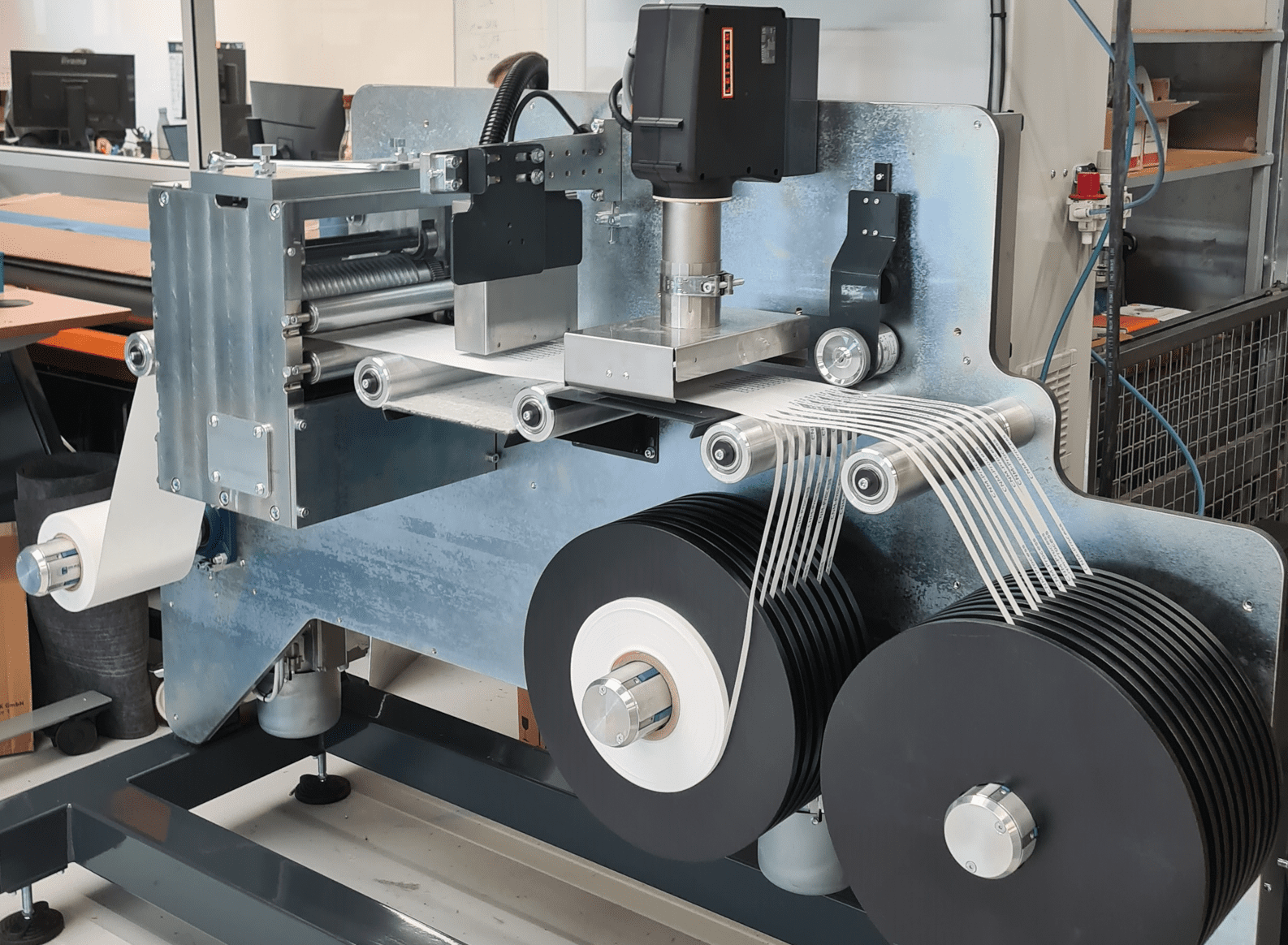

Longitudinal slitting machine

Customer business sector: Foams manufacturer

Customer business sector: Foams manufacturer

The customer need a solution for their filter manufacturing process. They need to insert a 10 mm wide strip that they want to print and personalize with their customers’ brand (EOM). Two important aspects need to be taken into account: a quick and easy solution for cutting a 170 mm wide material into seventeen 10 mm wide strips, and an ink printing solution. This printing solution must be water-resistant and compatible with non-woven, a porous material. In addition, the solution had to be solvent-free, environmentally friendly and in-line, enabling continuous operation at a sufficiently high speed to meet the customer’s requirements.

The solution implemented by CNM consisted in using a cutting unit equipped with rotating tools specially designed to produce a continuous 10 mm wide strip. At the same time, several manufacturers of printing systems were studied in order to find a suitable technical solution, including one or two print heads, for integration into the production line. This solution must be compatible with porous materials.

In addition, a drying system was integrated to increase the speed of the production line. The configuration also includes two winders for finished rolls and a flange system to facilitate product recuperation.

The customer is completely satisfied with the machine, which perfectly meets his needs. Simplicity of use was a key point for him, so the machine is designed to be used with a single process and a single product, without complex adjustments. Simply place the material, tighten the cutting block with a torque key to obtain uniform cutting pressure on both sides of the cutting tool. When the cycle is started, the tensions are automatically adjusted, and the printer is controlled by the system’s PLC. In addition, a flange system has been installed, providing a simple, cost-effective solution for output slug recuperation.