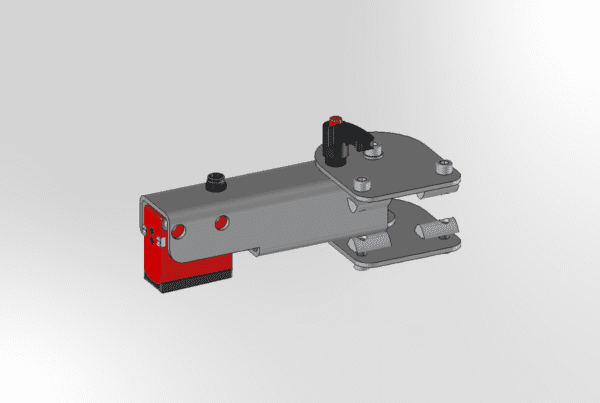

Machine

PRO WINDER P/V

A versatile solution with vision system

All kinds of materials

Vision system integrated

Wide tension range

Smooth and flexible

Advanced work cycle management

Specially designed to accept all types of rolls: This machine is equipped with a vision system that allows unwinding of badly wound / faulty rolls while maintaining perfect process quality.

The Pro Winder can unwind any material with total control, whether elastic, fragile, thick, with irregular edges, sliding… Once the machine has been set up, it is possible to save the parameters linked to the material thanks to a recipe function.

The unwinder operates with several tension management modes, each with different advantages that together cover any needs you may have.

Thanks to advanced tension management, we ensure long-term process reliability, with, for example, material loop management at the start of the cycle or end-of-roll / material break management.

Depending on the production machine associated with the unwinder, several working modes are available. One mode is optimized for continuous unwinding of the material, a second is designed for frequent stops, and a third is designed for material to-and-fro, with the unwinder able to unwind and then rewind while maintaining the same tension.

Technical data

Tension

Touch screen display

Rolls Ø max.

Working speed

Widths

Max. rolls weight

Available options

- Included: Vision system

- Included: External sensor in loop mode

- Line encoder

- Input output module

- Castors + Floor fixings

Included: Vision system

Useful solution for badly wound or faulty rolls

Automatic realignment

Defect detection

Flags detection

Our vision system works on all types of materials and is particularly effective on materials with irregular edges.

It allows realignment on the material edge or through a liner or on a pattern.

The same system can detect material flags/ defects and send back their position to eliminate the corresponding areas.

Included: External sensor in loop mode

Indispensable solution for elastic materials

Ideal for materials such as Lycra, foam rubber…

Allows tension-free unwinding by external equipment

Prevents material retraction after cutting

The material loop passes over the puppet, and a laser distance sensor measures the height of the loop. The motor adapts its speed so as to maintain the loop at a constant height, thus making it possible to follow variations in line speed.

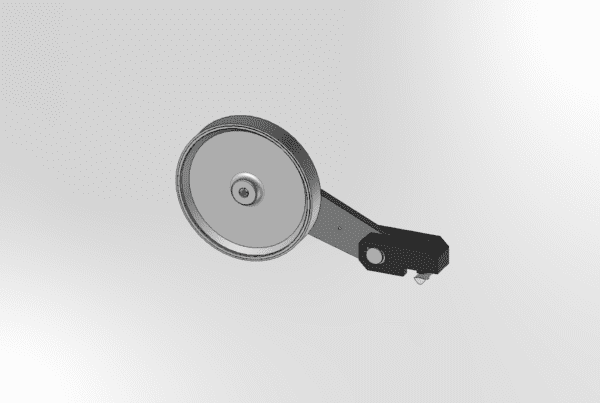

Line encoder

Essential solution for printer applications ( reverse detection allows rewinding)

Roll yardage control

Facilitates inventory management and process

HMI feedback (length remaining / unwinded)

Can measure in winding and unwinding mode

A line encoder calculates the unwind length, which can be either in contact with the material or with a detour roll.

Information from the line encoder are displayed on the HMI, with a dedicated space on the home page for entering desired production lengths.

INPUT OUTPUT MODULE

Solution for exchanging information between machines

Start & Stop

Direction (forward / reverse)

Ready

Enables exchange of information between machines: Start and Stop / Direction (forward and backward) /Ready.

Minimum configuration: one input and one output available on the production machine.

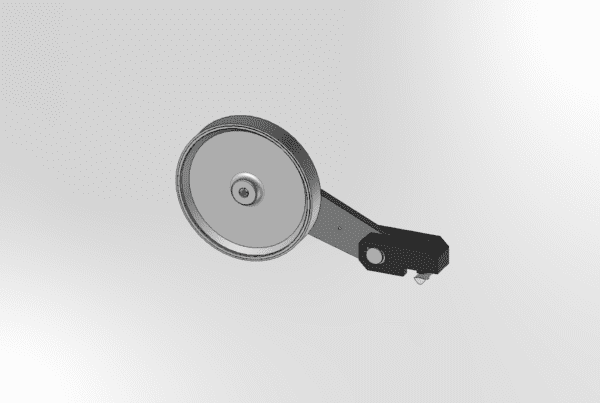

Castors + Floor fixings

Useful when the machine is frequently moved

Easy to move and position

Simplified maintenance access

4 PU-coated, braked swivel castors are fitted in place of the machine feet.

An indexing clamp system enables the machine to be quickly secured to the floor.