CoNverting lines

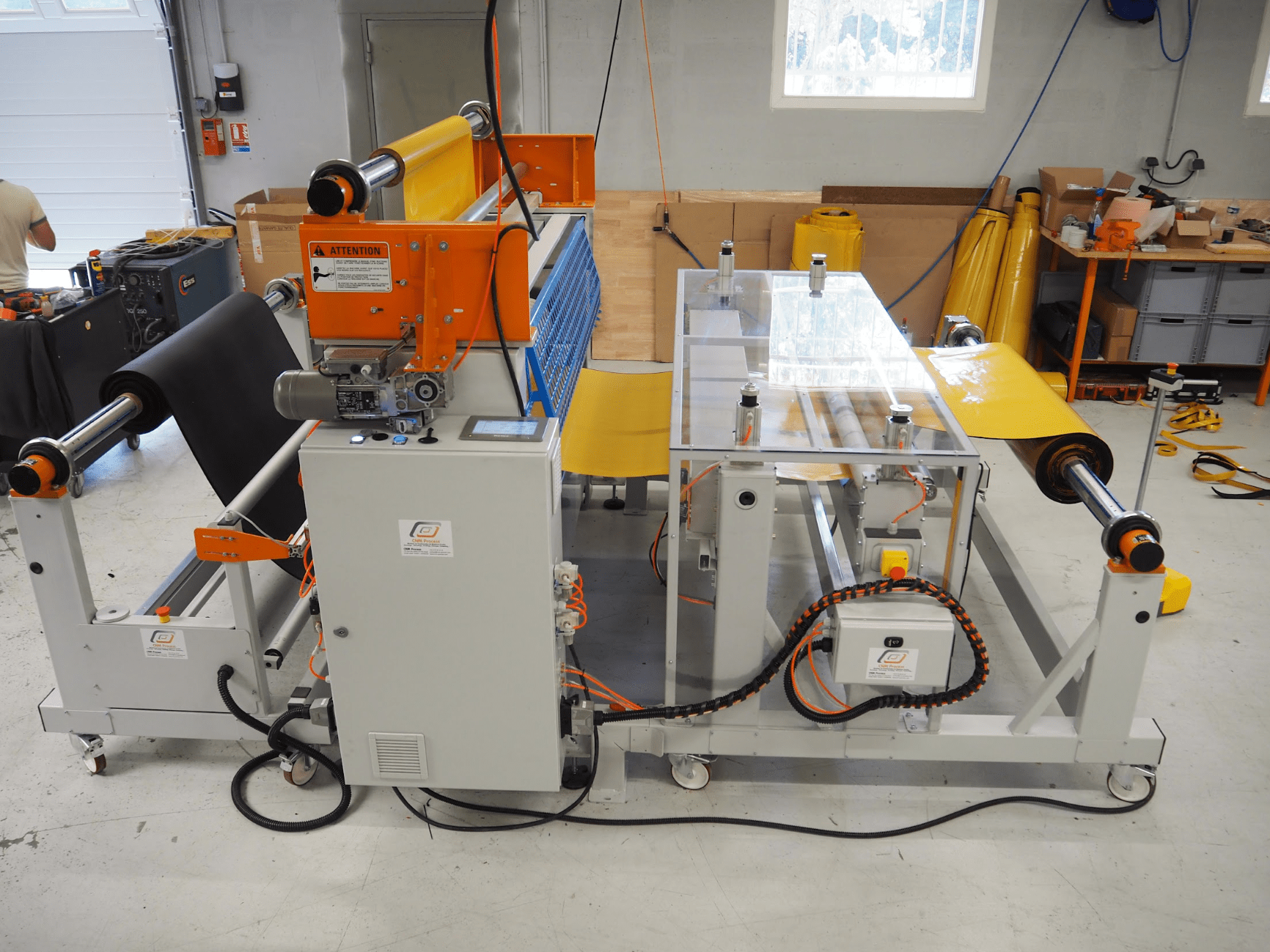

EcoLam

EcoLam versatility and simplicity

EcoLam, a simple, effective solution

This machine is a simplified version of its big sister, the Prolam, and is designed to provide an efficient, affordable laminating solution while maintaining high quality results.

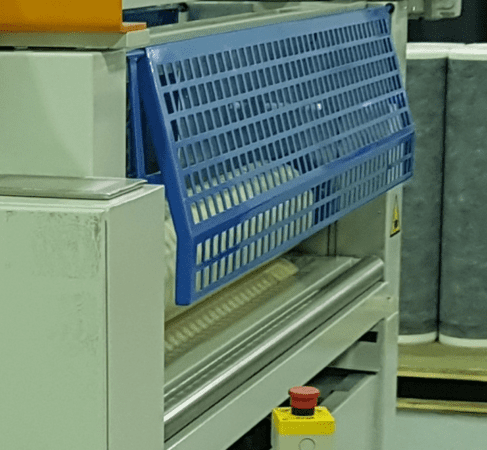

The machine is modular. Agile production changes are made possible by recipes recording. The work area is protected by mechanical covers, a reliable and economical solution.

7″ touchscreen display for complete cycle control, with dynamic graphic interface showing the process:

- Working speed

- Winder/unwinder management

- Length management

Available modules

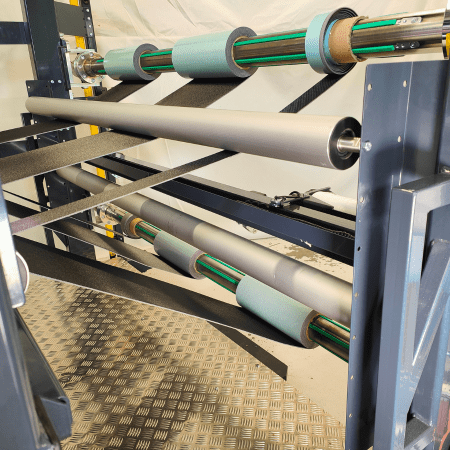

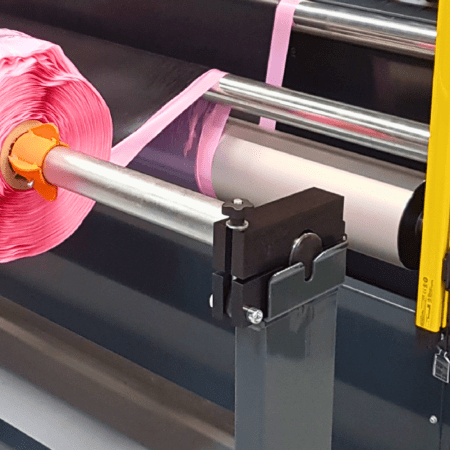

Unwinder - Rewinder

Tension control

Constant tension

Ease of use

Rigid materials

Unwinder - Rewinder

Mechanically braked

Mechanically adjusted tension

Ease of use

Very economical

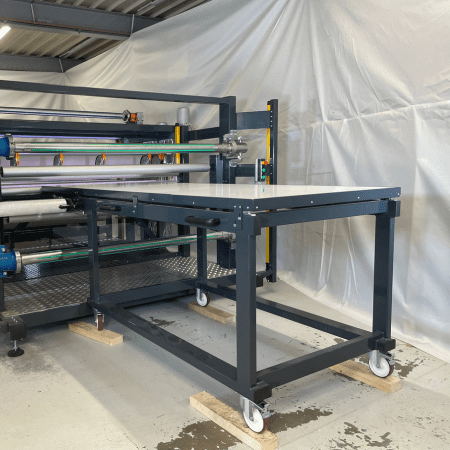

Table

Input - Output

Working with plates

Fast locking

Economical

Calendering

Hot calender

Mechanical protection

Adjustable stops